Newman Roller Mesh has for the past 10 Years Dramatically Evolved and Changed from its Engineering starting from 20 Years ago, and has developed into:

Super High-Strength & High-Durability Filaments.

25% to 50% Stronger than Most Other Brands.

Mesh last much longer, more durable, and can withstand more abuse.

Large Percentage of Open Area.

Thin Thread Diameters.

High Quality and Consistency.

NRMesh has No Newton Tension Limitations to be able to print.

NRMesh Prints at Any Newton Tension Level: Low, Medium, High, and Ultra-High Newtons.

Printing at Low-Tension Newton Levels Will Still Not Produce the Higher Quality, Faster Speeds and Efficiencies that Higher-Tension Newton Levels Provide. The Higher the Newtons, the Faster you Print, and the Better the Quality and Efficiencies for almost every printing application in Graphics, Textile or Industrial.

NRMesh has been in continuous production use for printing high-volume to low-volume for the past 20 Years all over the world. The engineering continues to evolve and improve.

High-Tension Printing Control of Interface Pressure

Measuring Mesh Snap-Force Non-Uniform Pressure Chart

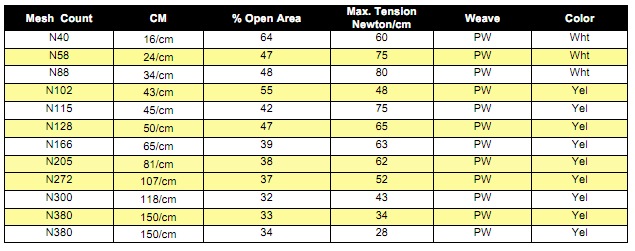

Newman Roller Mesh Specifications - Download mesh chart

Newman Roller Mesh Application Guide - Download mesh application guide

Widths- 60 80 100 120 and others. White mesh available in some mesh counts. N460, N420, N350, N182 And Others available if correctly needed.

See other mesh Brands-Recommended for Realistic and Sustainable Newton Levels.

ADDITIONAL BENEFITS USING HIGHER and CONSTANT NEWTONS USING NEWMAN ROLLER MESH

MANUAL PRINTING:

Dramatically Faster Print Stroke.

Less Squeegee Drag.

Less Squeegee Pressure.

Reduced Physical Exertion.

Reduced Potential Injury to Wrists and Forearms.

Helps Prevent Carpel Tunnel Syndrome.

AUTOMATIC PRINTING:

Faster Press Set-Ups

Tighter Registration. (Dot On Dot)

Much Faster Printing Speeds (> 1,000 prints / hour.)

High Ink Velocity Results in Complete Ink Discharge and Transfer.

Little or No Ink Build-Up on Back of Screens.

Sustained Constant Tension means No Press Tweaking and Adjusting during the run. Set It and Forget It.

Low squeegee pressure Squeegees stay sharp, last longer.

Thinner, Smoother Ink Deposit.

Faster Flashing with Less Heat Saves Time & $$$$.

Super smooth even emulsion coating results in maximum image definition.

COMPLETE INK RELEASE RESULTS IN:

Less Dry -In (especially for all water based inks)

Little or No Ink Build-Up on Back of Screens.

Reduced contact time with print surface.

Instant release from print surface. - Pallet adhesive lasts longer.

Razor sharp printed detail.

SCREEN RECLAIMING:

Faster Reduced Labor Cost

Less Chemicals Saves $$

Requires lower washer pressure

Reduced machine maintenance

Noticeably less Haze or Ghosting. Higher print quality, better ink release.

CUSTOMER REVIEWS - NEWMAN ROLLER MESH BY-THE-YARD

Our screens are all Newman Roller frames with a combination of Newman Roller meshes and standard meshes. The Newman mesh is tensioned between 44 to 65 Ncm2. The standard meshes are tensioned between 26 to 42 Ncm2. On both types of mesh this allows the off contact to be 1/32" (.03125"). This has eliminated screen distortion caused by excessive off-contact distances. It also allows us to use minimal squeegee pressure to transfer the ink from the screen to the substrate.

In relationship to the two different types of meshes, we have seen that the Newman roller mesh is stronger than conventional or regular meshes. Even at the high tensions, these meshes are more durable. We believe the screens with Newman Roller mesh will last longer. Also, we have seen measurable improvement in the detail of our prints with Newman roller mesh; stronger and more durable mesh and distortion-free prints, with improved detail. We like what we saw.

Monty L. Hand

Company X/DTI, Inc.

Columbus, OH

We started to convert our shop over from stretch and glue screens to the Newman Roller Frame system. In addition to using the frames, we also employed the pin registration option and have been talking advantage of all of the benefits ever since.

As you know we print exclusively for No Fear Inc. and their production demands push us to the limit and hold us there. We need to maximize every available production minute and this system has helped us to do that.

By having all of our current designs filed on the carrier sheets we can set up, expose and process the screens for an average 6 color design in under 30 minutes with a two person crew. These screens can then be taken to any of our M&R machines loaded in, and registered in 10 minutes. Once squeegees, floodbars and inks are in, a test print will tell us if there are any adjustments to be made and we are ready to print. This system will beat the fastest manual set up person anytime.

The Newman Roller Mesh is a big time saver as well. Our screens average 55 to 60 newtons on each of the 5 mesh counts we use and once they reach this point they are stable. We can cycle them through thousands of impressions and multiple reclaiming with just a few newtons being lost, this translates into less labor costs due to less retensioning.

We are committed to the Newman products because Newman is committed to making screen printing easier and more profitable.

Dan Goldberg

General Manager

La Costa Silkscreen, Inc.

Carlsbad, CA

Mind's Eye Graphics, Inc. is a textile screenprinter which was established in 1984. I personally have watched & participated in the maturation of the screenprinting process from the late 1970's. We purchased our first M-1 roller frame in 1986, that's right just 1. Today our inventory numbers close to 500 in assorted sizes and applications.

In addition to our inventory of roller frames we purchased one of your first manual pin registration systems at the SPAI show in 1994. The impact of the pin registration system on our production was dramatic to say the least.

After a short learning curve the system started to make it's presence known throughout the shop. As every printer since the beginning of time our shop had come to rely on certain so called shortcuts and bad habits to correct problems as they would occur in the sceenmaking & printing process.

However, if you use a shortcut once to correct a problem you have saved time, if it becomes part of daily operations you are compromising efficiency. Stretch Devices' pin registration system has prevented us from accepting compromise as we have integrated your products into our production process.

To best describe the impact of your products on our operation I must use the word Professionalism. By this, I mean that using a pin registration system things are done right the first time almost every time. From art creation, initial registration, imaging, and setting up the press problems are reduced or eliminated by the system. When problems do occur the troubleshooting time is greatly reduced because of the predictability of the registration process.

Additionally, screen room staff training is much quicker as the science of screen printing is further defined by products such as yours.

Stretch Devices has played an important part in the current success that our industry in general and Mind's Eye in particular is experiencing. As a user of your products in our manual operation since the very beginning, when it came time to enter into the arena of automatic production your roller frames were the only option for Mind's Eye. A 10/c 12 station press was our choice and the first item-on my list of options/requirements was compatibility with our proven Stretch Device's technology

A mandatory part of our upgrade was 100 Newman frames factory-stretched with Newman Roller Mesh as part of the initial production line package. This decision was based on minimizing the learning curve as we converted from manual to automatic printing. By using high tension minimum off contact printing I knew I could rely on consistent results as we offered this new service to our clients.

Gregory F. Kitson

President

Mind's Eye Graphics, Inc.

Decatur, IN