The Newman PinLock Registration System has been developed as a comprehensive strategy to increase productivity in the The Graphics printing application by dramatically lowering the on-press preparation time. This system, specifically designed for use with Newman Roller Frames®, which utilizes high-tension, distortion-free printing, consists of 3 distinctive steps: Film-to-Screen Alignment, Screen Exposure and On-press Alignment.

STEP 1: Art Preparation

Provided are pre-punched Carrier Sheets made of optically clear and stable base polyester. These sheets have been punched by our specially designed equipment, resulting in an impressive tolerance of + or - .0002. All art is aligned on these Carrier Sheets, while pinned to the carrier sheet Pin Bar Strip or Grid Layout Board. The beauty of this method is its ability to evaluate the film positive alignment or "trueness" and then correct or compensate for any irregularities, distortions, or imperfections that may be inherent in the film positive. This technique promotes objective evaluation of the "alignments" before spending valuable on-press time compensating for such deviations.

STEP 2: Film-to-Screen Alignment

Film positives, correctly attached to the Carrier Sheets are placed on a PinBar that is attached to the print-side (or mesh-side) of the Newman Roller Frame®.

The PinBar has stainless steel pins that fit perfectly into the stainless steel PinLock castings on the Newman Roller Frame®. Each film positive is transferred to the print-side of the screen mesh with clear tape on a flat table or surface. Screens are then placed in the exposure unit – as many screens as will fit at one time. As a result, the images on all the screens become correctly aligned with one another. The exacting relationships of art registration and film-to-frame alignments are unique to the Newman PinLock Registration System.

STEP 3: On-press Alignment

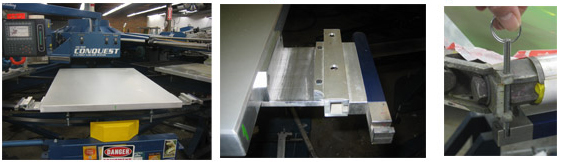

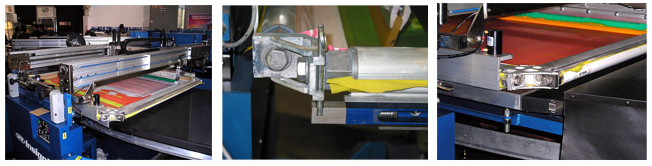

The Newman PinLock Registration System is well suited for simple or any demanding art separation. Well-maintained printing machines, combined with a high-level of proficiency between the operator, art and screen room personnel, can provide very excellent results for even the most demanding butt-register art. The Newman PinLock Press Fixture is adapted directly to the press. The placement of the fixture will depend on the press manufacturer and press model. Examples are shown below of just a few of the graphic presses that we have successfully retrofitted to our system. The Newman PinLock Registration System is adaptable to almost all graphic presses on the market today.

Pin Fixture mounted on the side of press bed. (Press shown below: M&R Conquest)

Pin Fixture mounted on the side of press bed. (Press shown below: M&R Insignia)

Pin Fixture mounted on the front of press bed. (Press shown below: M&R Saturn)

Start-up Kits are available for both Manual and Automatic presses. The Newman PinLock Registration System will save you money and increase your productivity in a very short amount of time when a 100% commitment is dedicated to the system.