The Newman Roller Mesh Snap Panel is the ultimate combination of Mesh and Stretching Technology and has Dramatically Evolved and developed into:

Super High-Strength & High-Durability Filaments.

25% to 50% Stronger than Most Other Brands.

Mesh last much longer, more durable, and can withstand more abuse.

Large Percentage of Open Area.

Thin Thread Diameters.

High Quality and Consistency.

Newman Roller Mesh Snap Panels Snaps into your roller frames in 15 seconds!

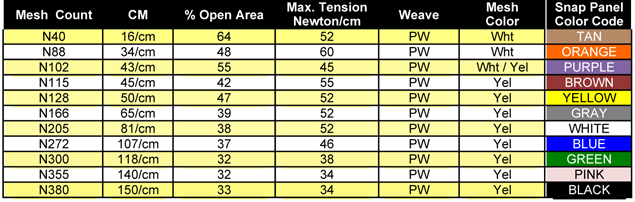

Newman Roller Mesh Snap Panels are color coded for each mesh count.

Newman Roller Mesh Snap Panels are provided pre-cut to our standard size frames and models. Refer to Tension Chart below.

Below is a video showing how our Newman Mesh Snap Panels simply "snap" into the frame in 10 seconds or less while keeping the frame flat after stretching.

NRMesh has been in continuous production use for printing high-volume to low-volume for the past 20 Years all over the world. The engineering continues to evolve and improve.

High-Tension Printing Control of Interface Pressure

Measuring Mesh Snap-Force Non-Uniform Pressure Chart

Newman Roller Mesh Snap Panel Specifications - Download Snap Panel Mesh Chart

Newman Roller Mesh Application Guide - Download Mesh Application Guide

NEWMAN ROLLER MESH SNAP PANEL TENSION CHART

Newman Roller Mesh Snap Panels are provided pre-cut to our standard size frames and models indicated below.

Frame Model / Sizes: MZX-UL model and sizes 18"x20"ID, 23"x26"OD, 23"x28"OD and 23"x31"OD.

Frame Model / Sizes: M3-UL model and sizes 23"x31"OD, 23"x33"OD, 23"x36"OD and 25"x36"OD.

See other mesh Brands Tension Chart for Recommended Realistic and Sustainable Newton Levels.

ADDITIONAL BENEFITS USING HIGHER and CONSTANT NEWTONS USING NEWMAN ROLLER MESH

MANUAL PRINTING:

Dramatically Faster Print Stroke.

Less Squeegee Drag.

Less Squeegee Pressure.

Reduced Physical Exertion.

Reduced Potential Injury to Wrists and Forearms.

Helps Prevent Carpel Tunnel Syndrome.

AUTOMATIC PRINTING:

Faster Press Set-Ups

Tighter Registration. (Dot On Dot)

Much Faster Printing Speeds (> 1,000 prints / hour.)

High Ink Velocity Results in Complete Ink Discharge and Transfer.

Little or No Ink Build-Up on Back of Screens.

Sustained Constant Tension means No Press Tweaking and Adjusting during the run. Set It and Forget It.

Low squeegee pressure Squeegees stay sharp, last longer.

Thinner, Smoother Ink Deposit.

Faster Flashing with Less Heat Saves Time & $$$$.

Super smooth even emulsion coating results in maximum image definition.

COMPLETE INK RELEASE RESULTS IN:

Less Dry -In (especially for all water based inks)

Little or No Ink Build-Up on Back of Screens.

Reduced contact time with print surface.

Instant release from print surface. - Pallet adhesive lasts longer.

Razor sharp printed detail.

SCREEN RECLAIMING:

Faster Reduced Labor Cost

Less Chemicals Saves $$

Requires lower washer pressure

Reduced machine maintenance

Noticeably less Haze or Ghosting. Higher print quality, better ink release.