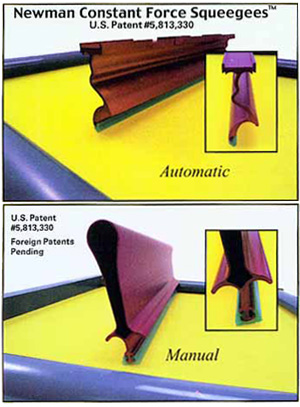

Newman "CONSTANT FORCE" Squeegee™

- Eliminates squeegee length variations caused by sharpening and solvent attack which changes the squeegee flex angle.

- NEVER sharpen another squeegee blade. Simply replace the tip when needed at 1/2 the cost of a conventional squeegee.

- Minimal squeegee pressure and angle adjustment are required with each print run since the squeegee dimension and flex angle are constant.

- Uniform ink film thickness is easily achieved.

- Improved color and print definition using less squeegee pressure.

- Unique design constantly rolls & mixes the ink keeping it fluid and smooth

- Reduces carding since the ink uniformly tracks down the frame.

- Reduction in ink climbing up the handle.

- Specially formulated urethane tips in various durometers will typically last 6 months to 2 years.

Easy clean up - no screws to trap ink.

PREPARED AND WRITTEN by DON NEWMAN

After 12 years of developing the economical NEWMAN CONSTANT FORCE SQUEEGEE (on average 1/2 the cost of a conventional squeegee) the squeegee is no longer a variable.

The conventional squeegee varies its length due to sharpening combined with solvent attack, which changes the flex angle of attack on the ink. This changes the pressure on the ink significantly during long print runs and between subsequent print runs. Like screen tension, the conventional squeegee is a larger and more significant variable than first meets the eye.

The NEWMAN CONSTANT FORCE SQUEEGEE has constant length since it is not sharpened; the entire tip is simply exchanged. The Squeegee Holder also cannot be attacked by ink and chemicals like conventional squeegees, which gradually change their flex angle. This new squeegee has constant length, constant flex angle and constant pressure on the ink every time you use it.

You will achieve faster set-up times because there is no need to adjust the squeegee up or down due to the length of different squeegee according to how many times the squeegee has been sharpened.

The replacement tips, in various durometers, are made of specially formulated urethane and for many applications will last 6 months to 2 years.

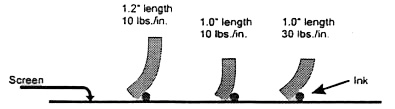

1/8" sharpening of a conventional squeegee radically changes the squeegee stiffness, flex angle, angle of attach on the ink, and the required pressure on the ink. As the conventional squeegee becomes shorter from sharpening, the squeegee increase its stiffness dramatically – not directly proportionately – but changes by the 3rd power of the new shorter length (L3).

By example: a 75 durometer squeegee with 1.2" length (past the holder) with flex approximated 3/8" with 5 lbs./inch of pressure. By sharpening the squeegee to 1.0" long, the same 5 lbs./inch of pressure causes the squeegee to stand up straighter with only approximately 1/8" flex. To bring the flex back to 3/8", now about 30 lbs./inch of squeegee pressure is required. This will change the ink deposit and detail. The approximate numbers vary greatly with various screen tensions, off-contact, ink rheology, squeegee durometer and type, print speeds, substrate variations, and aesthetic goals.

These approximate numbers and the general pictures below are provided for the purpose of conceptionalization only.

These approximate numbers and the general pictures below are provided for the purpose of conceptionalization only.

Remember that new technology is rarely a quick fix. Improvements in print quality and speed usually comes at the price of hard work, testing, and an open mind to new possibilities. The printers that get better and faster every year are constantly testing, working harder, applying constant creativity, and more persistence than their competitors might think.

Data reference Equation: D = PL3

3EI

Prepared and written by Don Newman October 1997

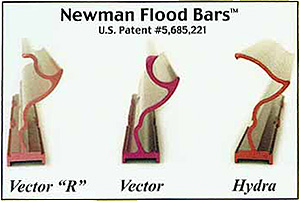

Newman Flood Bars™

- All Newman Flood Bars rotates the ink at high speeds and injects it into the mesh orifices.

- As you raise screen tension, printing speed increases and print quality improves.

- Newman Flood Bars are individually precision machined to create flatness and parallelism.

- All models are anodized for: greater wear resistance, ease of clean-up, and nick and wear tell-tale.

- The ends of the flood bars are precision feather radiused to

- prevent mesh wear and tear.

Flood Bar SPEED Test - White on Dark

| Newman " Hydra" Flood Bar 900 PCS/HR |

Conventional Flood Bar 650 – 700 PCS/HR |

|

|

Side by Side printing comparion for speed. Both images were printed on the same Newman frame with the same squeegee at the same speed. Only the FLOOD BARS were changed. Printing courtesy Anderson Studios Knoxville, TN |

|

| Good White Thin, Smooth Opacity Excellent, Fine Detail in on STROKE |

Poor Opacity & Poor Detail To achieve results "approaching" the results to the left, the press speed would have to be slowed to approx. 650-700 PCS/HR |

|

| The Result - Increased Print Speed While Maintaining Opacity & Detail |

The Flood Dilemma

In a typical 24" X 24" image size (61 X 61cm), using a 300/inch mesh (118/cm), there are amazingly 30 to 50 million mesh orifices. These mesh orifices are approximately only 36 microns (.0014") to 43 microns (.0017") in length and width. These very small orifices are also nearly as deep as they are wide (more than twice as deep as wide where a stencil is added).

Gravity can play little role in filling (or flooding) such small orifices since the ink's surface tension & the mesh's surface area generate far too much force and friction. Therefore, a traditional flood bar that pushes the ink across the screen with a mostly horizontal force will only create a large pool of ink on the top of these 50 million mesh orifices or at best, achieving only a slight penetration. Given the ½ to 3 seconds available during a typical print cycle, gravity can do little.

A traditional flood stroke leaves 30 to 50 million little orifices either unfilled or only slightly filled. This forces the squeegee to have in effect do two jobs - the flood bars job and the squeegees job. In order to accomplish this, the squeegee must add substantial pressure and also slow its speed down. In this way, the squeegee now must first fill 30 to 50 million small orifices, and then also, bring the mesh down to contact with the substrate allowing the ink sufficient time to both adhere and transfer as the screen snaps back up.

The Solution

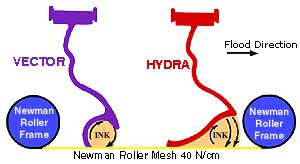

All of the Newman Flood Bars™ rotate the ink in a tight circle at high speed. This redirects and injects the ink directly downward into the millions of small mesh orifices. The inks own velocity is now filling all of the open orifices with almost no friction or pressure from the flood bar onto the mesh.

The Newman Flood Bar™ can successfully move ink at 2 to 3 times normal speeds. This is due to the redirection of the inks energy and the relatively large ink contact surface area of these new flood bars.

Now that the squeegee does not have to flood the mesh orifices, it simply can do its own job of ink adherence and transfer. This permits the squeegee to dramatically reduce its pressure and increase its speed while also gaining enhanced image brightness, detail, and coverage.

(See sample above of these results)

The Example

The ink is rotated at high speed & is injected downward into the mesh orifices. The inks velocity quickly does the work without "mesh to flood bar pressure". As the ink rotates it tracks straight down the screen with little spillage out to the sides reducing the need to "card" the ink back into the image area. In addition, water & solvent evaporation is reduced from their respective inks. The lower the screen tension, the slower the relative printing speed, quality, and consistency.

Due to differences in printing applications, ink viscosities, marketing, and aesthetic opinions, it is recommended that you experiment to determine which of the Newman Flood Bars™ or combination of the Newman Flood Bars™ will give you your optimum desired speed and quality results.